JH Robotics has engineered and built custom equipment for just about any application. Our team of engineers specialize in machine design, including both electrical and controls. Their preferred CAD platform is SolidWorks. However, they are capable of operating and receiving the majority of CAD system files.

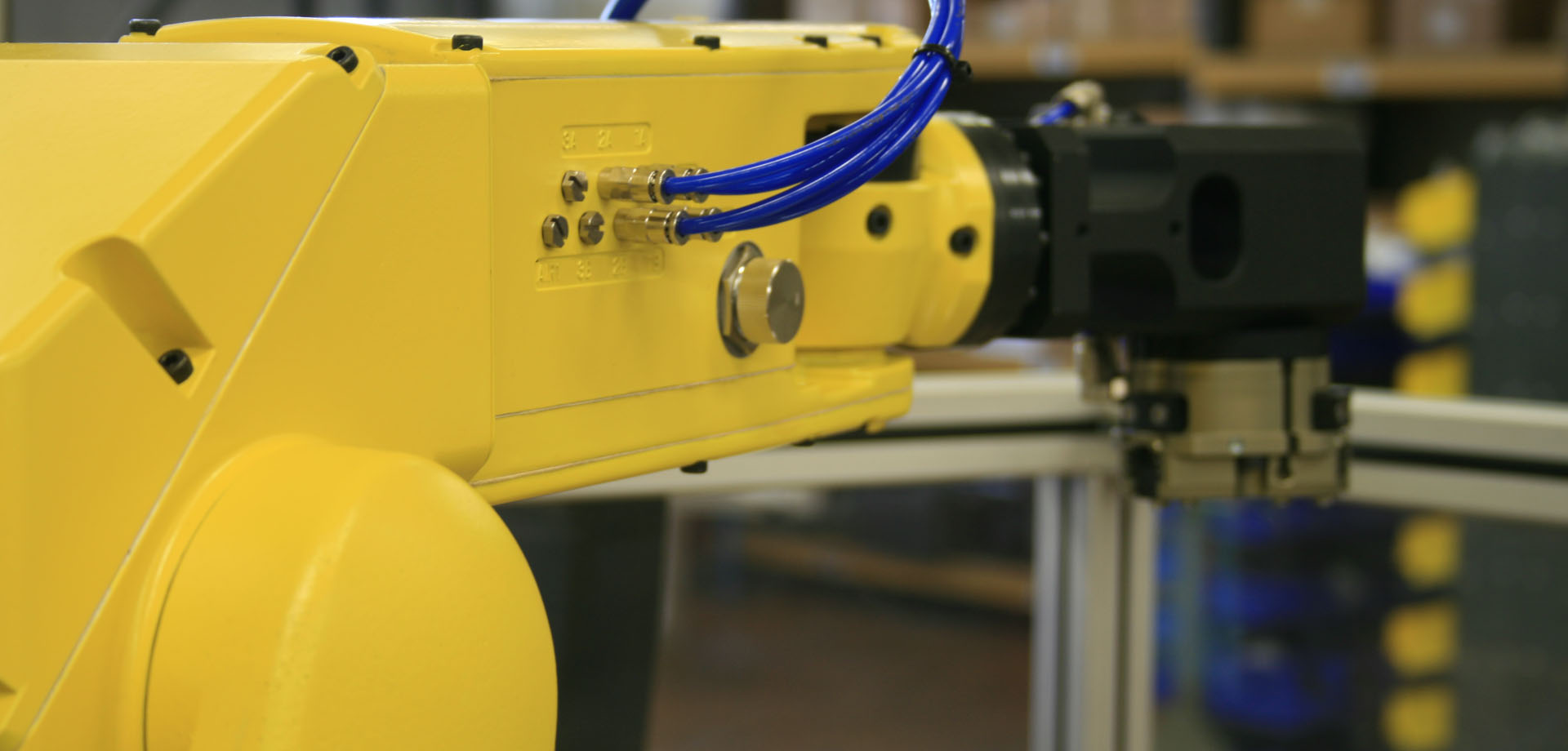

Our special machines demonstrate a wide range of capabilities, please view our Capabilities Brochure for more information. These special machines, when interfaced together with the FANUC robots, form the equipment which provides the complete automation system. The stand-alone custom machines are generally PLC controlled and can work automatically or as operator-assisted machines. If a FANUC Robot is involved with the custom machine, the FANUC Robot controller can run the entire system replacing the need for a separate PLC. In most cases the FANUC iPendant acts as the system HMI.

JH Robotics engineers write, design, and build all the software, hardware, and control panels for the Robots, PLC's, and HMI's in house. We are flexible enough to use your preferred PLC and HMI manufacturer, or we can select the best option for your application. We have experience with manufacturers such as, Allen Bradley, FANUC, GE, Koyo, Modicon, Siemens, and various others.

Communication with the customer through all phases of the build from start to finish is key to a successful system. With each system a project engineer is assigned who follows the system through design, manufacture, build, debug, test, customer runoff, installation, warranty, and finally service. He is the person who works with the customer on scheduling, financials, and changes - always a constant on the project.