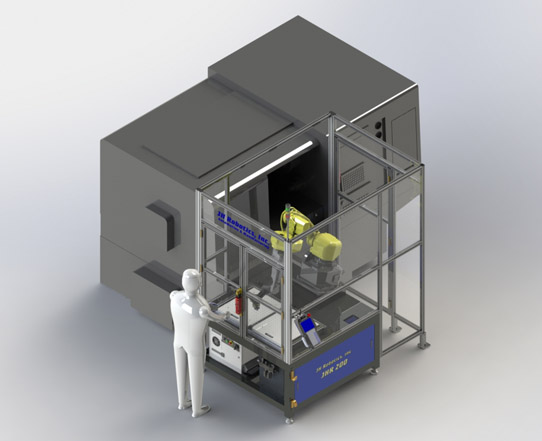

JHR-200 Machine Tending Robot

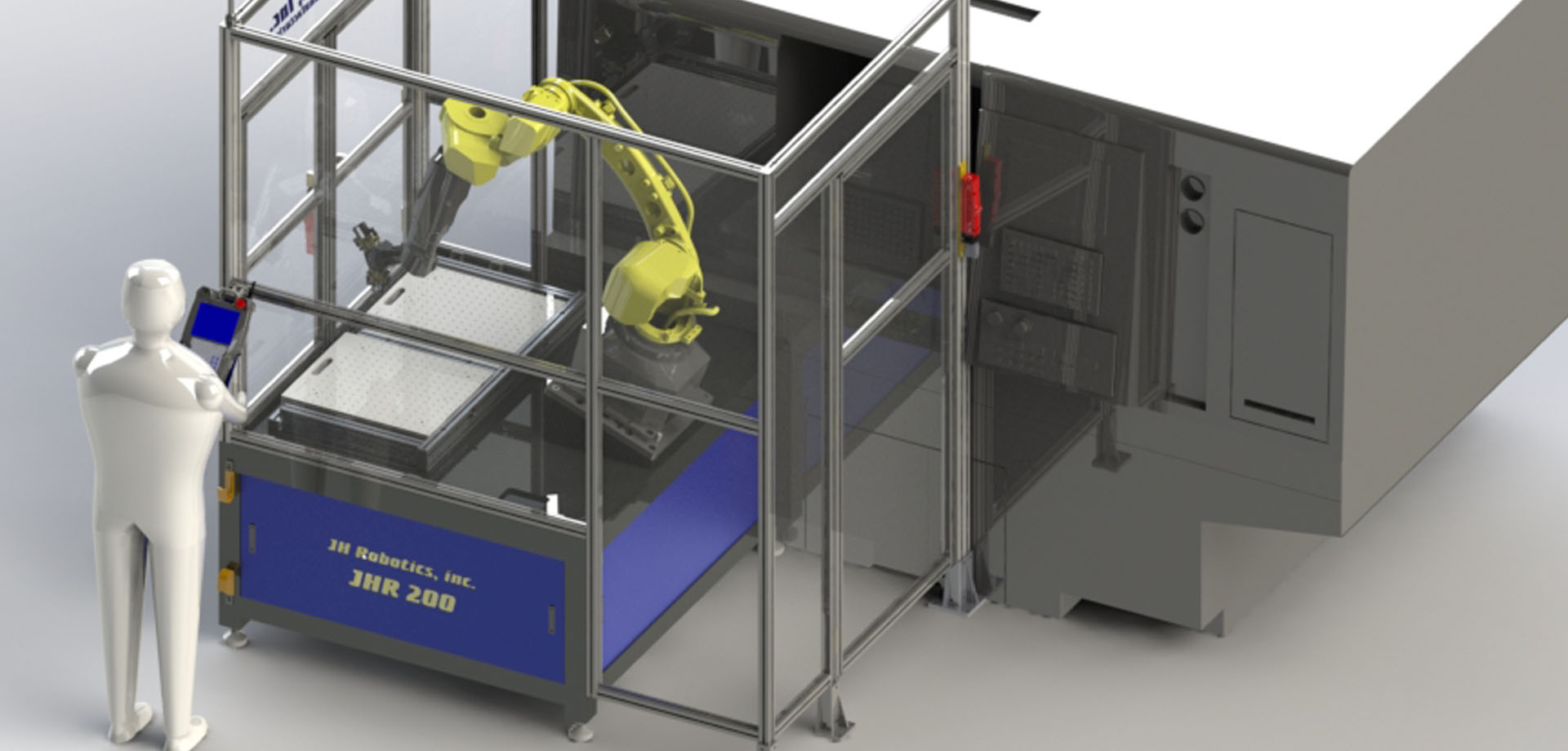

JHR 200 SERIES (M10iD with (2) Tray System)

JH Robotics new family line of machine tending robots are designed to be cost competitive, with shorter turn-around time, and versatile in any atmosphere. The JHR 200 is shown at base price and have multiple options to add and choose from.

-

System Features

- Pre-engineered, proven and easy to use robot machine tending cell.

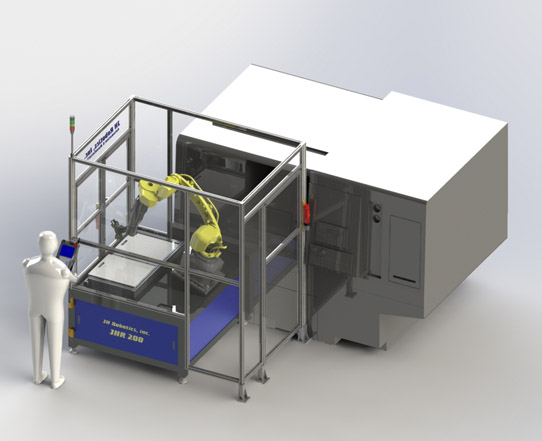

- Adapts to any new or existing CNC Lathe, Mill, Grinder or EDM.

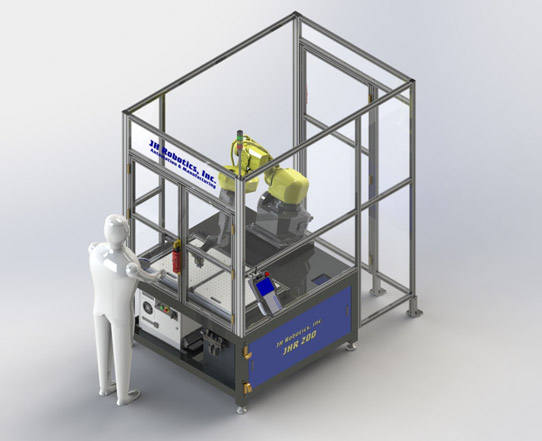

- Featuring the FANUC M10iD/12 six axis robot with R-30iB Plus Mate Controller and Touch Screen Teach Pendant - robot mounted at an angle to optimize reach.

- Easy to use system controls - custom JHR operator panel on the touch screen teach pendant is used for system interface and messaging.

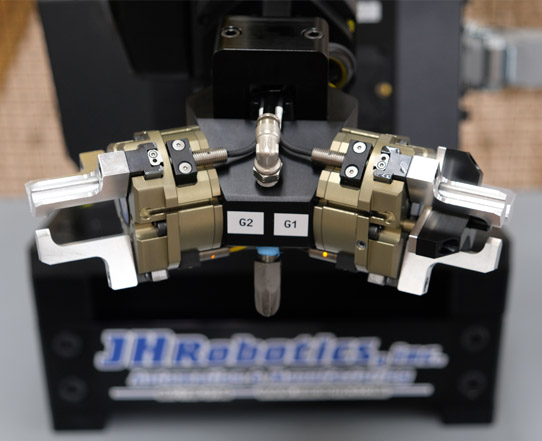

- Custom robot end of arm tooling sub-assembly included with (2) high-quality, Schunk-brand pneumatic actuators to allow for simultaneous load/unload cycles.

- Pneumatic valve & sensor block added to J3 robot joint for end of arm tooling control.

- Robot dress-out of air lines and sensor cables in the FANUC Solution Arm reduces system cost and improves reliability.

- One-piece welded steel frame construction for simplified install and relocation.

- Extrusion guarding system with safety interlocked access doors.

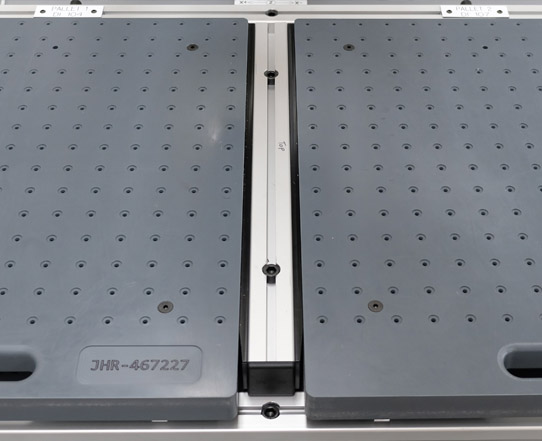

- 2 Tray Guidance System for part input/output:

- Tray working space approximately 17.5" x 18.5"

- Each tray can be used for input and output of parts

- Must stop robot motion and open door to perform tray changes

- Pre-written & optimized robot software structure included for picking & placing from trays and for picking & placing from machine tool. Software and HMI designed to allow end user to setup parts easily on their own.

-

System Benefits

- Drastic productivity increases created by:

- Fast and repeatable load/unload times

- Reduced machine down-time - no breaks, lunches, sick days or vacation days

- Lights out operation - run robot on off-shifts & weekends

- Product quality improvements created by:

- Smooth and repeatable load and unload conditions

- Finished parts are kept separated on trays eliminating part to part contact

- Elimination of human error

-

Specifications

- FANUC M-10iD/12 robot - 12kg total payload, 1441mm reach

- FANUC software options: Collision Guard, DCS Position & Speed Check & Panel Wizard

- FANUC Terminal I/O Converter Board - includes 24Inputs/28Outputs

- For a two-actuator gripper assembly, the robot can handle up to 7.5lb parts

- For a single-actuator gripper assembly, the robot can handle up to 15lb parts

- Part capacity example: each tray holds (64) 1.5" OD x 4" long parts (128 parts total)

- Typical Machine Dimensions: 78" long x 54" wide x 90" tall

- Utilities required for install: 208V-three phase-60Hz power, 80psi air

-

System Options

- Turn-key Part Tray & Gripper Finger Tooling

- Turn-key Software setup and testing

- 2-Drawer System for part input/output - allows continuous robot operation during tray changes or part restocking

- Robot-mounted Blow-off

- Part Audit Chute

- Long Arm Robot (FANUC M-10iD/10L model - 1636mm reach, 10kg payload))

- Collaborative Robot (FANUC CR-15iA model - 1441mm reach, 15kg payload)

- iRVision Capability (for picking randomly oriented parts or basic inspection)

- Part Deburr

- Part Wash/Dry

- Part Gauging

- Part Marking/Labeling

- Machine Base Docking System (quick connect mechanical and electrical hardware)

- Various Communication Protocols (FANUC I/O Link, ProfiNet, Ethernet IP, etc.)