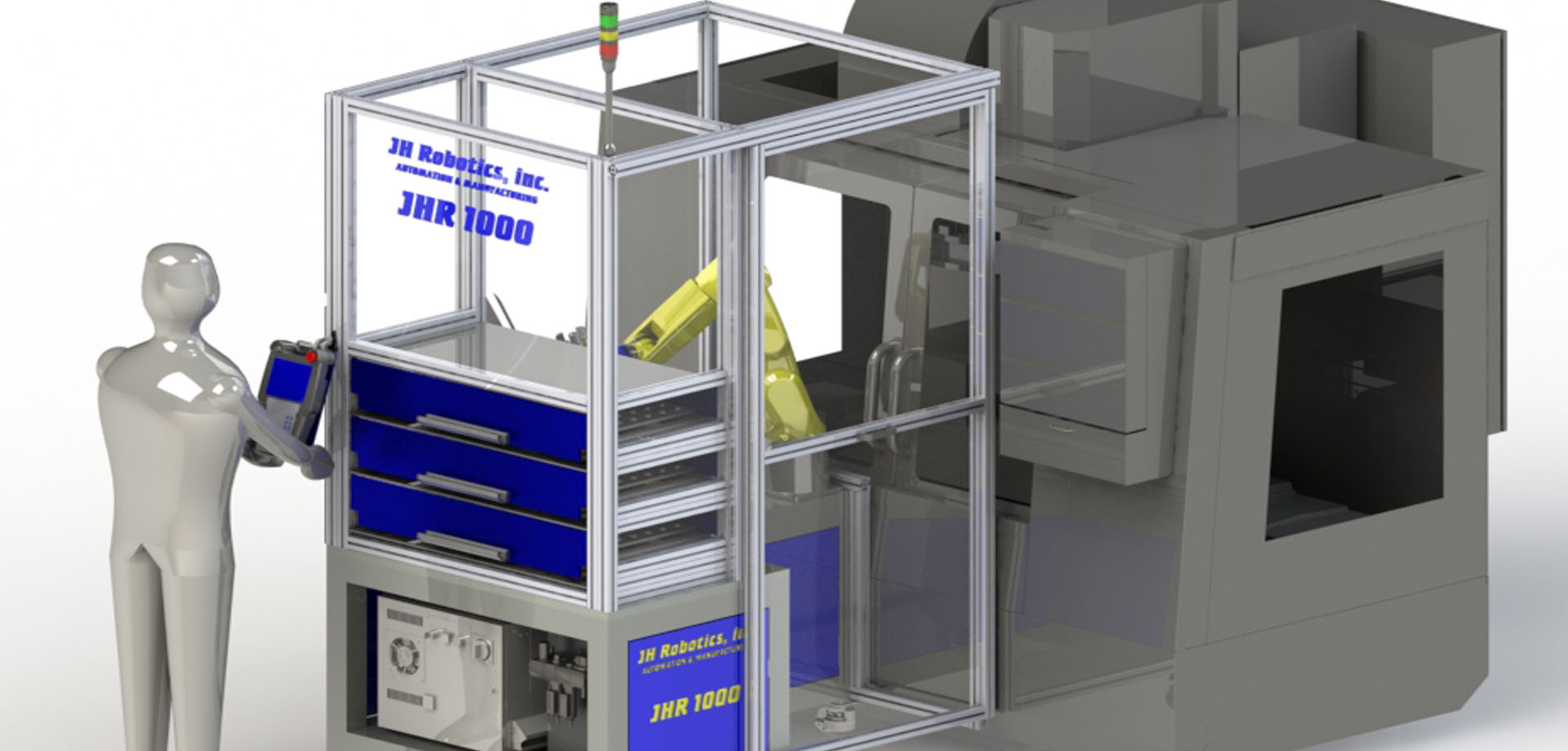

JHR-1000 Machine Tending Robot

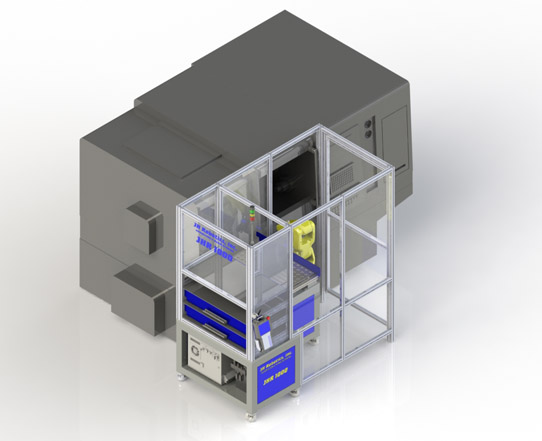

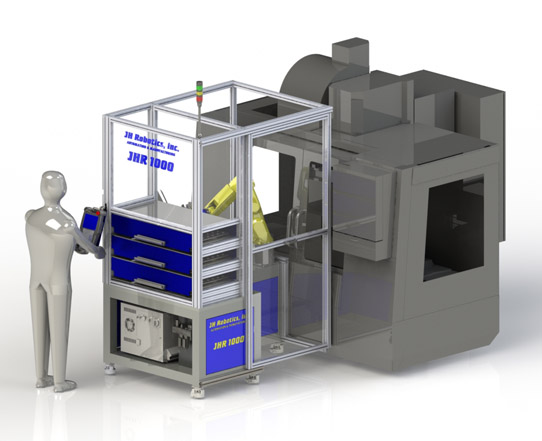

JHR 1000 SERIES (LR Mate with Vertical 3-Drawer System - holds 6 trays)

JH Robotics new family line of machine tending robots are designed to be cost competitive, with shorter turn-around time, and versatile in any atmosphere. The JHR 1000 is shown at base price and have multiple options to add and choose from.

-

System Features

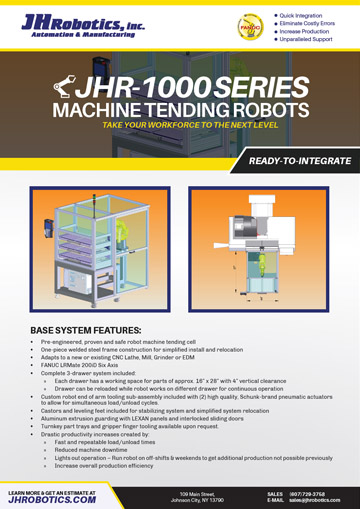

- Pre-engineered, proven and easy to use robot machine tending cell.

- Adapts to any new or existing CNC Lathe, Mill, Grinder or EDM - various layout configurations available

- Featuring the FANUC LR Mate 200iD six axis robot with R-30iB Plus Mate Controller and Touch Screen Teach Pendant.

- Easy to use system controls - custom JHR operator panel on the touch screen teach pendant is used for system interface and messaging.

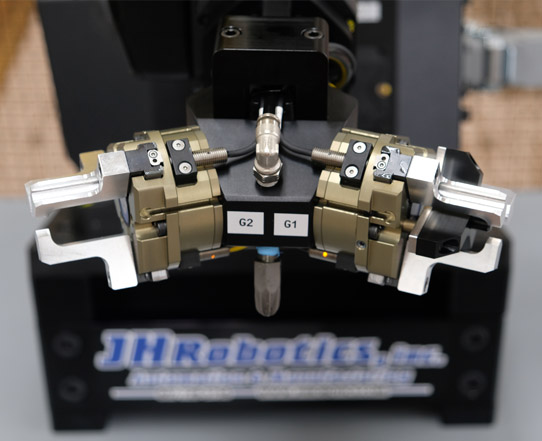

- Custom robot end of arm tooling sub-assembly included with (2) high-quality, Schunk-brand pneumatic actuators to allow for simultaneous load/unload cycles.

- One-piece welded steel frame construction for simplified install and relocation.

- Extrusion guarding system with safety interlocked access doors.

- 3-Drawer part infeed/outfeed system included:

- Each drawer holds two part trays - each tray has a working space of approx. 14" x 16".

- Three drawer positions (operator, neutral and robot) allow drawers to be emptied and reloaded while robot works on different drawer.

- The number of drawers can be tailored per system, and will be based on the longest part length - parts longer than 4" will result in less drawers, etc.

- Pre-written and optimized robot software structure included for picking and placing from trays and for picking and placing from machine tool. Software and HMI designed to allow end user to setup parts easily on their own.

-

System Benefits

- Drastic productivity increases created by:

- Fast and repeatable load/unload times

- Reduced machine down-time - no breaks, lunches, sick days or vacation days

- Lights out operation - run robot on off-shifts & weekends

- Product quality improvements created by:

- Smooth and repeatable load and unload conditions

- Finished parts are kept separated on trays eliminating part to part contact

- Elimination of human error

- Highest rated and most reliable robot brand in the world - FANUC ROBOTICS

- FANUC along with JH Robotics provide unparalleled support and service for the life of the system

-

Specifications

- FANUC LR Mate 200iD robot - 7kg total payload, 717mm reach

- FANUC software options: Collision Guard, DCS Position & Speed Check & Panel Wizard

- FANUC Terminal I/O Converter Board - includes 24Inputs/28Outputs

- For a two-actuator gripper assembly, the robot can handle up to 5lb parts

- For a single-actuator gripper assembly, the robot can handle up to 10lb parts

- Part capacity example: each tray holds (48) 1.5" OD parts (96 parts total)

- Part capacity example: each drawer holds (96) 1.5" OD x 4" long parts (288 parts total)

- Drawer weight capacity: 100 lbs/each

-

System Options

- Turn-key Part Tray & Gripper Finger Tooling

- Turn-key Software setup and testing

- Robot-mounted Blow-off

- Part Audit Chute

- Long Arm Robot (FANUC LR Mate 200iD/7L model - 911mm reach)

- Collaborative Robot (FANUC CR-7iA/L model - 911mm reach)

- iRVision Capability (for picking randomly oriented parts or basic inspection)

- Part Deburr

- Part Wash/Dry

- Part Gauging

- Part Marking/Labeling

- Machine Base Docking System (quick connect mechanical and electrical hardware)

- Various Communication Protocols (FANUC I/O Link, ProfiNet, Ethernet IP, etc.)