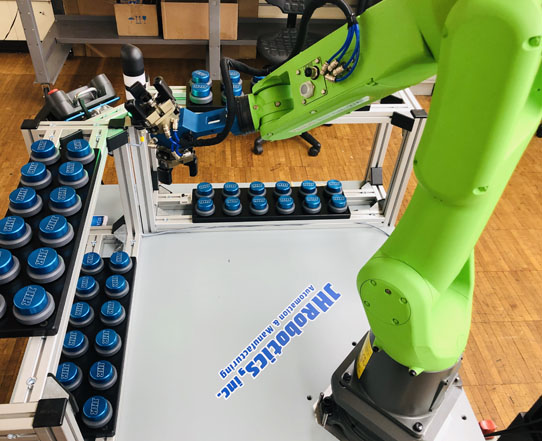

JHR-Sidekick CR7 Collaborative Robot

JHR SIDEKICK SERIES (CR-7iA Collaborative Robot with Double Rack System)

JH Robotics new family line of machine tending robots are designed to be cost competitive, with shorter turn-around time, and versatile in any atmosphere. The JHR Sidekick CR7 is shown at base price and have multiple options to add and choose from.

-

System Features

- Pre-engineered, proven, and safe robot machine tending cell

- Features FANUC CR-7iA/L collaborative six axis robot with R30iB Mate Plus controller and iPendant

- Robot will stop safely in the event of contact with a human operator, allowing the system to safely operate without safety fences or sensors

- Adapts to a new or existing CNC lathe, mill, grinder, or EDM

- One-piece welded steel frame construction for simplified install and relocation

- Robot can be pushed out of the way at any time with minimal force

- 4 tray infeed/outfeed system

- Each tray has a working space for parts of approx. 6" x 20" with 4" vertical clearance

- One tray can be reloaded while robot works on another tray for continuous operation

- Custom robot end of arm tooling sub-assembly included with two high quality, Schunk-brand pneumatic actuators to allow for simultaneous load/unload cycles

- Casters and leveling feet included for stabilizing system and simplified system relocation

- Turnkey part trays and gripper finger tooling available upon request

- Drastically increases productivity of machine tool by:

- Lights out operation - run robot on off-shifts and weekends to get additional machine utilization

- Increase overall production efficiency

- Consistent and fast machine load/unload times

- Greatly decreases machine operator labor

-

System Options

- Turnkey part option

- Custom engineered gripper fingers, part trays, and programming to automate production of a part of your choice

- Highspeed option

- Adds an area scanner to the system which allows the robot to accelerate to faster speeds when an operator is not present

- Robot mounted blow-off option

- Blow-off nozzle mounted on robot end effector assembly & required valving and plumbing to use for automated part or work-holding blow-off