JH Robotics AutomationNation™

The Benefits of Adding Machine Tending Robots to Your Manufacturing Workforce

Machine Tending Robots offer many benefits for businesses who are serious about increasing productivity, safety, and repeatability in their manufacturing process.

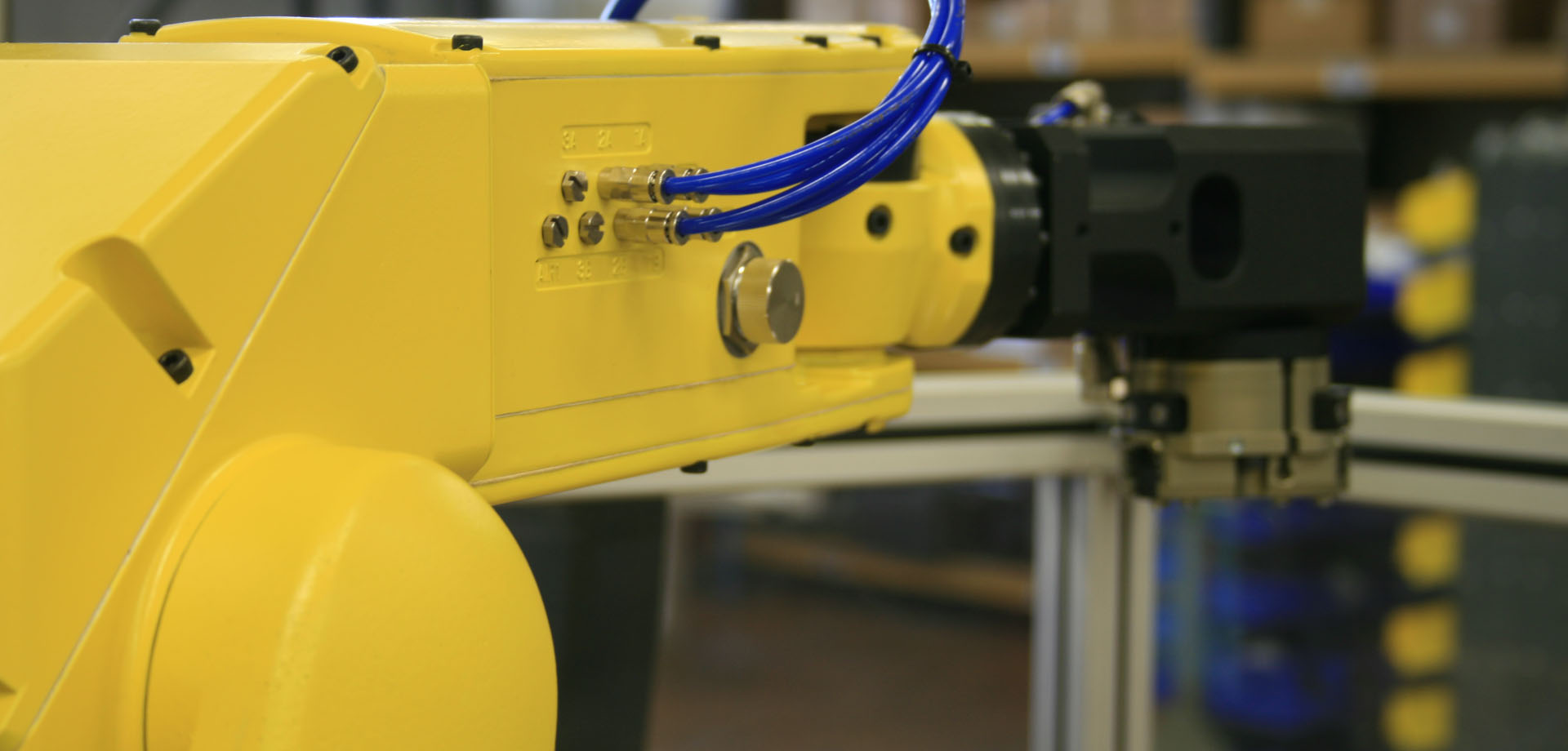

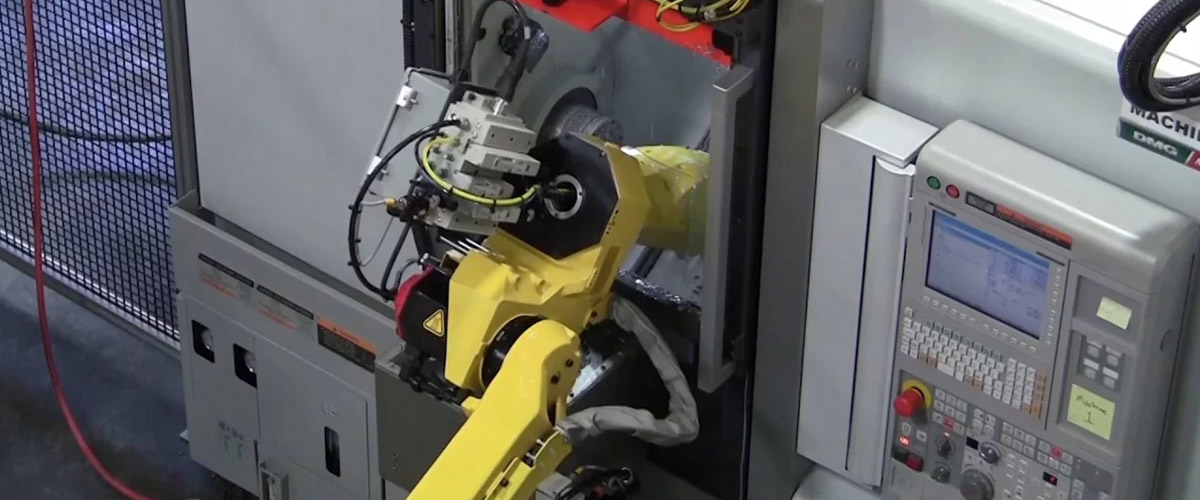

Machine tending automation is the process of integrating one or more robots into the manufacturing of what are typically machined parts by a CNC (computer numerical control) machine. In the majority of applications, raw materials are loaded from a tray into the CNC machine, processed, and then unloaded by the same robot to a finished parts tray. By utilizing other forms of automation, such as conveyors and pick and place robots, much of the CNC machining process can be fully automated without any human interaction.

The difference between machine tending and typical material handling is accounted for in the added complexity involved with machine tending. The robot will need to communicate with the CNC machine to understand when the part has finished processing, open the door, and time out multiple other functions that are key to the manufacturing process.

Machine Tending Processes that are Commonly Automated

While manufacturing robots can be integrated in a virtually unlimited number of configurations, the most common everyday processes that are commonly automated include:

- Milling

- Turning

- Injection Molds

- Stamping

- Punching

- Grinding

- Welding

Benefits of Integrating Machine Tending Robots

There are many benefits, both obvious and some lesser known, to integrating machine tending robots into your workforce.

1. Machine Tending Robots Increase Up-time

When compared with manual loading and unloading, machine tending robots will dramatically improve uptime and throughput of your manufacturing process.The only time a machine needs to stop is during routine maintenance, meaning that you’ll benefit from “lights-out” manufacturing, a very expensive endeavor when manually tending a machine 24/7.

2. Manufacturing Processes Become More Predictable and Repeatable

When your machine tending robots are properly configured and programmed, you’ll be sure no mistakes occur during the manufacturing process.This results in an increase in quality of the machined parts and an increase in the accuracy of those parts – meaning less material waste and company time in fixing human errors.

3. Machine Tending Robots Make for Safer Manufacturing Conditions

One of the most dangerous aspects of the manufacturing chain is undoubtedly the manual load and unload of parts during the manufacturing process. We all know that workplace accidents are a direct result of becoming too complacent and comfortable while operating a large piece of equipment like a CNC machine. By automating the tedious task of loading and unloading these machines, your business becomes a safer workplace for your employees and eliminates future lawsuits and compensation.

4. Machine Tending Robots Make for a Stronger Workforce

You may think that automating parts of your manufacturing process results in less employee morale and less hiring needs; however, studies have shown the exact opposite is true.By automating menial tasks such as loading and unloading machines, your workforce will become more empowered and allow your teams to focus on more mission critical aspects of the manufacturing process.

5. Machine Tending Robots Pay for Themselves Over Time

For all the reasons listed above, machine tending robots will save your company money during the course of their lifetime and eventually pay for themselves.By increasing throughput, decreasing material waste, increasing quality, and eliminating workplace accidents, a machine tending robot is an excellent choice in increasing the profitability of your business.

Speak with a Machine Tending Automation Expert Today

Our team is ready to meet with you at your manufacturing facility to speak with you regarding how we can integrate our line of machine tending robots into your manufacturing process and show you how we’ve helped other companies realize the benefits of automation.

Back to AutomationNation™ Blog